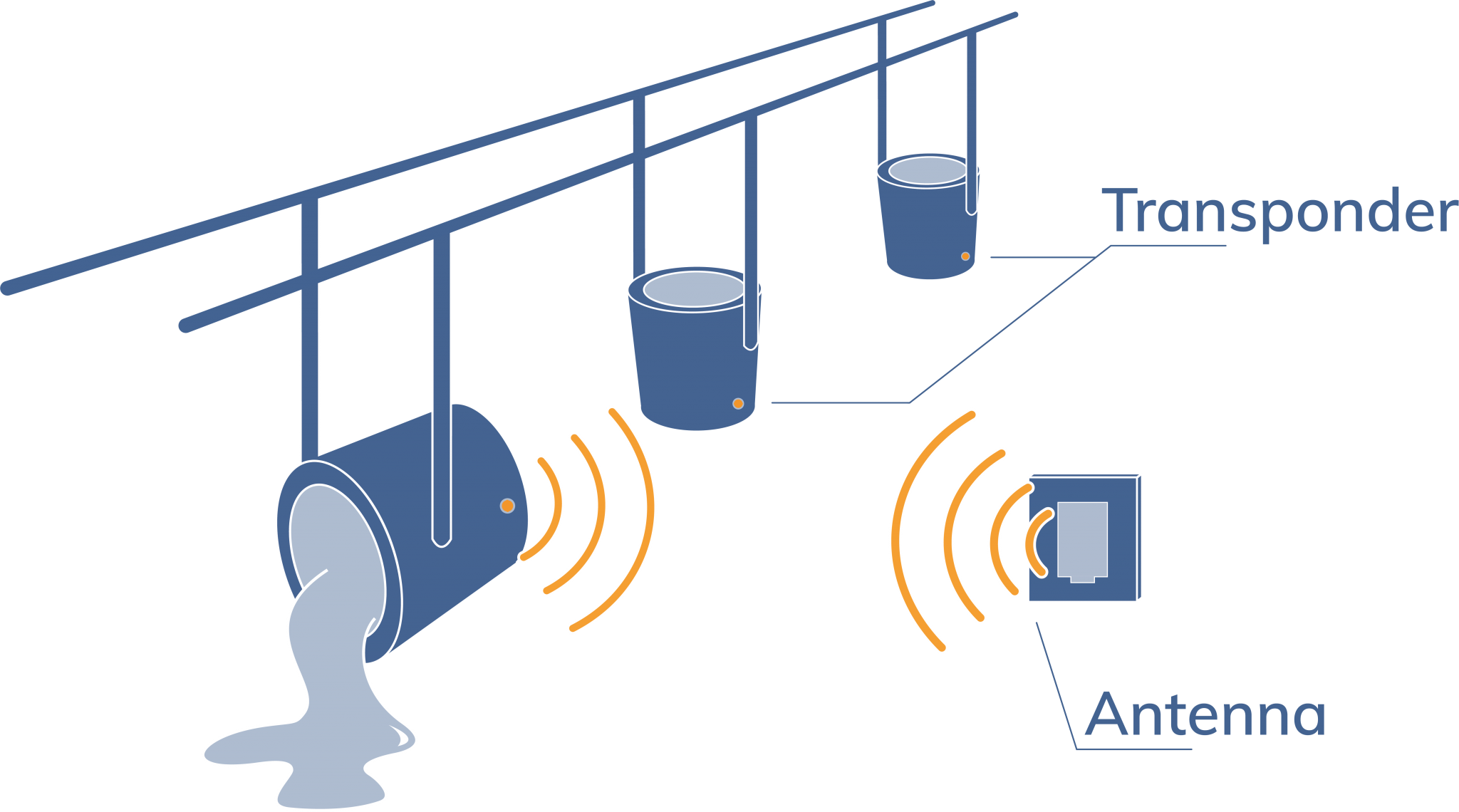

Ladle Tracking

The greatest challenges of a modern enterprise resource planning (ERP) system are the difficult and demanding environmental conditions within the steel production. High temperatures, mechanical stress and dirt are the main barriers for the implementation of a seamless batch tracking via RFID.

Our Solution

The sensor networks of sensideon enable the automatic capture of position and the generation of other related indicators such as the dwell time, in a difficult industrial environment. The passive and maintenance-free transponders were specifically developed for ladles and containers in the steel industry and function up to 400°C. This allows the mounting of the transponders directly on the ladle wall. This ensures the automatic detection via radio transmission. In the course of this, maintenance data for the ladles can easily be derived in addition to batch tracing using a system-integrated database. This allows a variety of optimizations such as a situation-oriented adjustment of the number of ladles in circulation and better planning and execution of maintenance activities. Thanks to SAW, the tracking function can be extended with an optional wireless temperature measurement at any time.

Customer Value

- Optimization of logistic processes

- Process control

- Batch detection

- Automatic data collection for maintenance

Area of Application

- Steel ladles

- Pig iron ladles

- Torpedo ladle

- Slag pots

- Scrap iron hollows

Contact Us!

Your question has not been answered yet? Find the right answers in our FAQs or contact us.