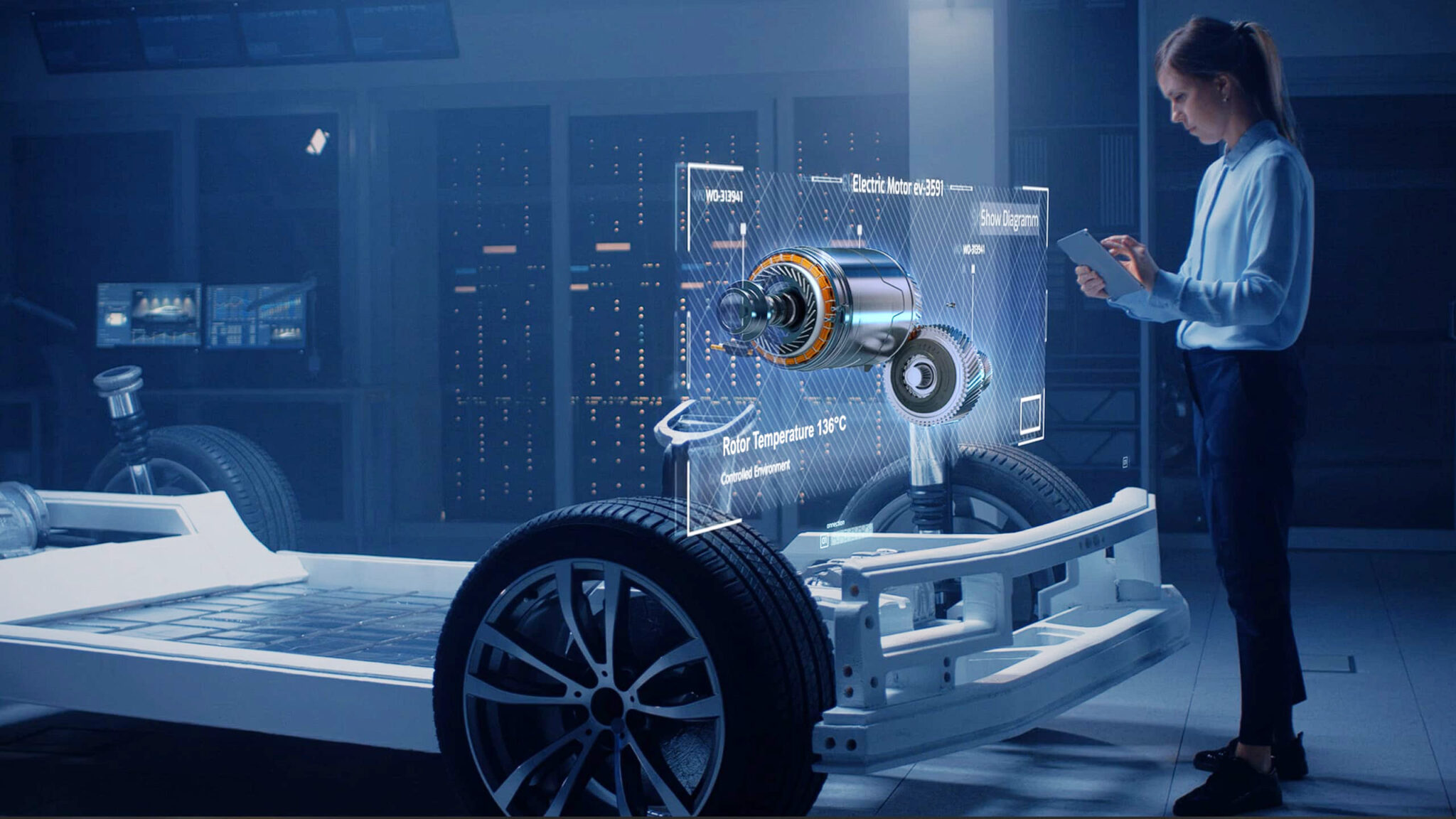

Sensor Telemetry & Rotor Telemetry for the highest demands of engine development for test benches and prototype vehicles

Rotor Telemetry SID2400: Our solution for temperature measurement on rapidly rotating and moving objects.

A particularly advantageous feature is that no additional electronics such as pre-amplifiers or similar circuits need to be integrated into the rotating part, as is the case with conventional sensor telemetry. The extremely compact design and low weight of our sensors allow for easy integration, even as a retrofit in existing machinery and vehicles.

The particularly robust and heat-resistant sensors ensure reliable measurements even at high temperatures, elevated rotational speeds, and under the influence of oil.

Our rotor telemetry systems find application, for example, in temperature measurement of permanent magnets or copper windings in electric motors for the automotive industry, in prototype vehicles, as well as in Formula racing.

In the field of testing and measurement technology, our innovative sensor telemetry systems push the boundaries of what was previously possible, enabling temperature measurement in areas that were previously barely accessible or difficult to reach.

Our sensor telemetry is characterized by a particularly compact and robust design. This allows for easy integration, even in complex engine and gearbox components with limited space availability – even as a retrofit if needed.

Save time, energy and weight

Customer Benefits:

- Robust, temperature-resistant, and durable

- Compact, no need for motor or shaft modification

- Easy integration into the vehicle

- Lightweight, contributing to weight savings

- Cost-effective

Sensor telemetry example applications:

- SID2400 – Smart Rotary Telemetry in Electric Motors

- piston temperature measurement in internal combustion engines

- temperature measurement in wind turbines

- temperature measurement in heavy-duty transmissions

- temperature measurement in heavy-duty drive shafts

Are you interested in sensor telemetry / rotor telemetry from sensideon or do you have any questions? Then contact us. You may also find the right answers in our FAQs.